Ten years ago it could take 3-5 years to develop a new car, today this can be reduced to 1.5-3 years. This is in part due to the use of digital twin technology, which can significantly accelerate development and shorten cycle times in areas such as driving simulation, automotive manufacturing processes and simulation optimisation.

More recently, similar technologies have emerged in the field of synthetic biology.

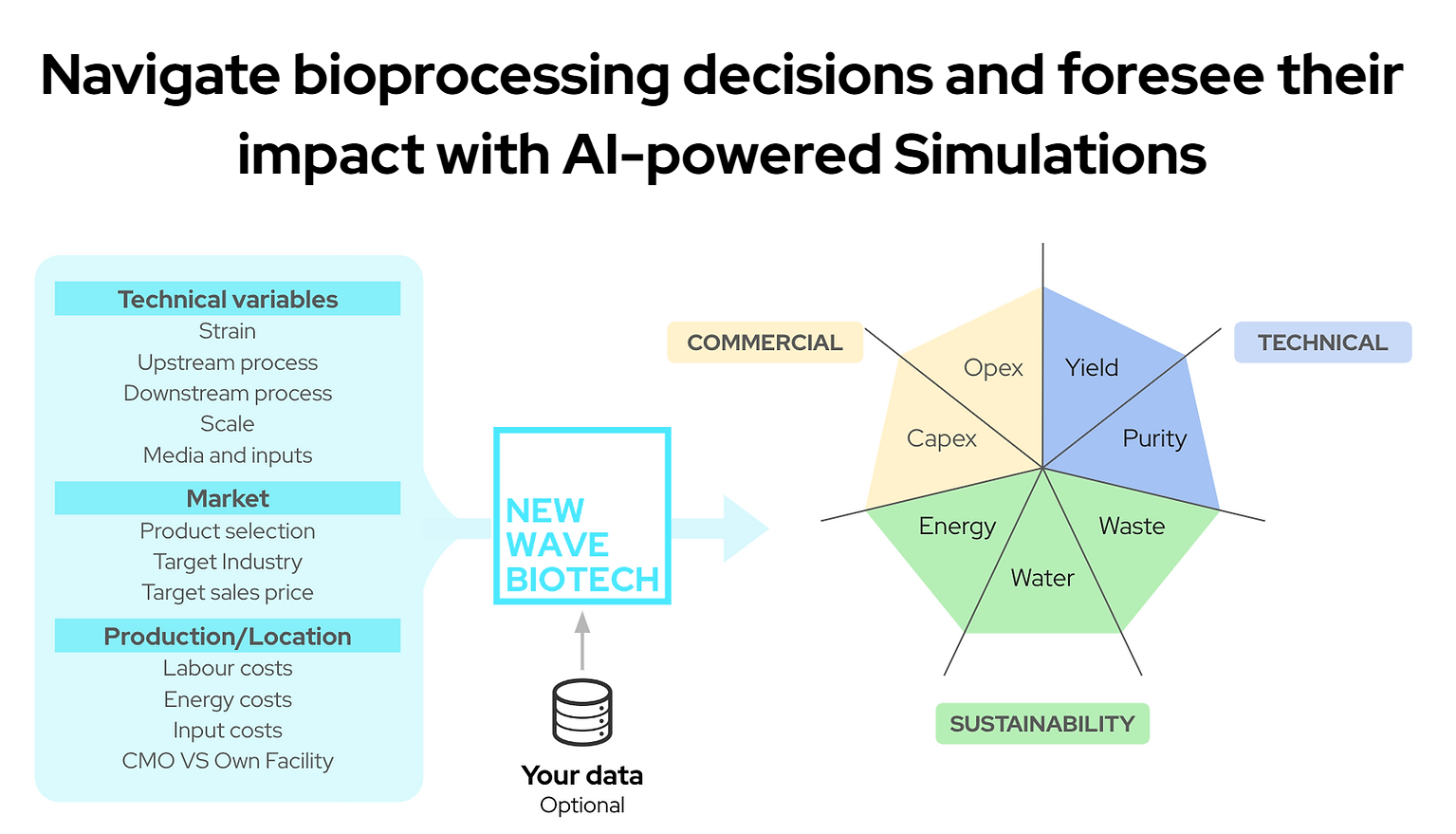

UK startup New Wave Biotech launched Bioprocess Foresight, the first biomanufacturing AI simulation platform, on 20 November 2024 to help biomanufacturing innovators achieve smarter design, faster commercialisation and greener scale-up.

According to BCG, by 2030, one-third of the world's manufacturing industry will be using synthetic biology technologies to replace unsustainable animal and petrochemical products, but 90 per cent of these technologies will not be able to be scaled up. That's because optimisation is difficult, process combinations can exceed a trillion, the average cost of conducting experiments is between $10,000 and $100,000, and it takes three to 10 years to scale from lab to market. Cost insights are also slow and expensive, with a single Techno-Economic Analysis (TEA) report costing between $20,000 and $40,000 and taking months to complete.

Several key technologies of the Bioprocess Foresight platform include end-to-end process modelling, downstream process simulation, machine learning and dynamic analysis. Using artificial intelligence simulation, it can predict quantifiable outputs, costs and sustainability impacts, improve as it learns from empirical data, and customise processes based on that data.

According to the official website, it can automate techno-economic calculations to aid selection decisions in a matter of hours for as little as £83 a month (rather than purchasing expensive industry reports).It is also relatively simple to operate, with analytics and visualisation tools available to navigate trillions of interconnected options and test scenarios by varying technical, market and production variables to provide intuitive designs for innovators from a wide range of industries.

The solution not only provides users with a holistic view of the process, but also offers actionable insights to identify R&D hotspots and the ability to virtually test infinite possibilities to understand possible outcomes.This will change the way biomanufacturing R&D is done.

Since its inception in early 2023, the company has received funding from the Innovative Engineering Biology Fund and the UK Research and Innovation (UKRI) Technology Mission Fund, and in December 23 entered into a partnership with Multus, a UK-based cell culture meat ingredient company, to leverage the speed and accuracy of AI's Bioprocess Optimisation software to scale up and improve the production of cell cultures using precision fermentation.some key ingredients economically.

Selection has long been one of the biggest headaches for biomanufacturers, who today must make informed predictions among thousands of potential choices and optimise accordingly,’ said Oli Hall, CTO and co-founder of New Wave Biotech. That's why we're launching Bioprocess Foresight, which we believe can help biotech innovators design better, commercialise faster and scale more environmentally friendly.